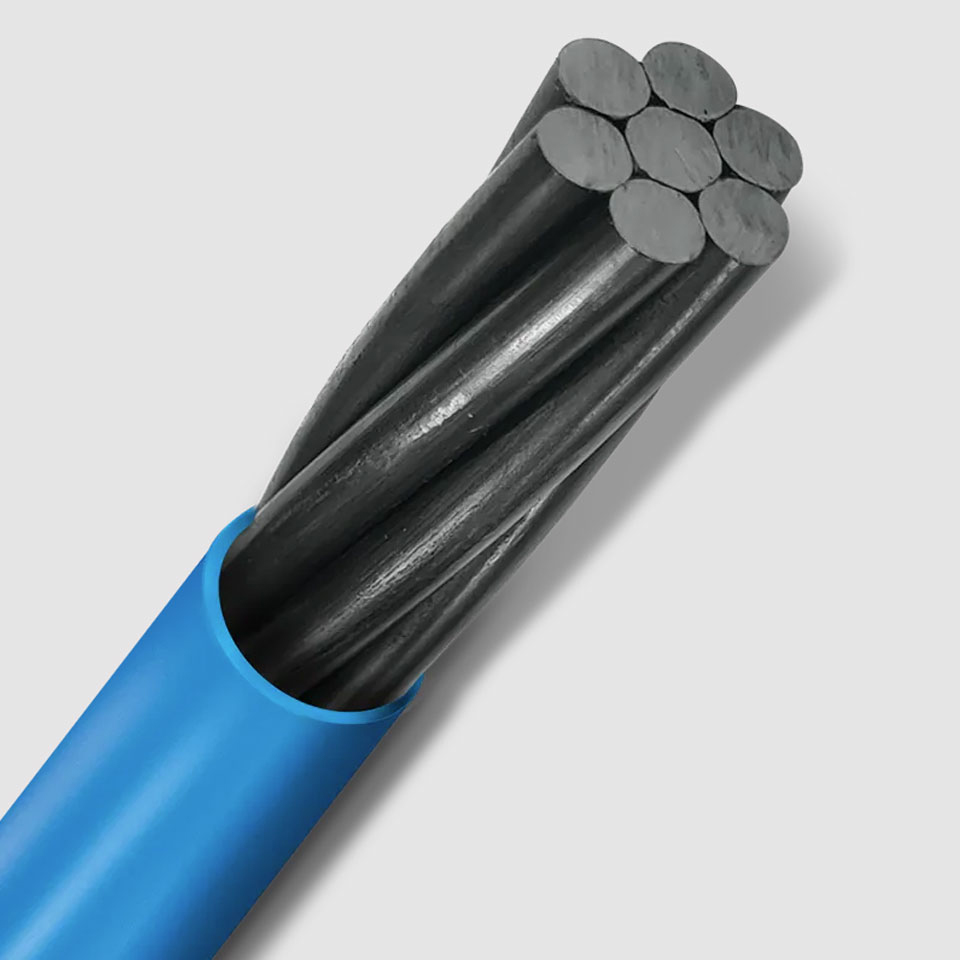

LRPC / HT Strands

What is LRPC / HT?

LRPC, an acronym for Low Relaxation Pre-stressed steel strands, represents the phenomenon where pre-stressed steel strands gradually release their initially applied stress in a mathematically proportionate manner as they become embedded in concrete.

The primary contributing factor to this stress reduction is the inherent property of steel known as stress relaxation. Through a thermo-mechanical process referred to as ‘stabilizing,’ steel’s tendency to “relax” under a stressed condition is effectively controlled. Low relaxation ensures that there will be no significant loss of tension over time, resulting in a sustained compressive force on the concrete.

Our Prestressed Concrete Steel Strands when embedded in concrete, release some applied stress exponentially. Low relaxation makes sure that, over time, there is negligible loss of tension. This gives lasting compressive strength to concrete, making it more durable.

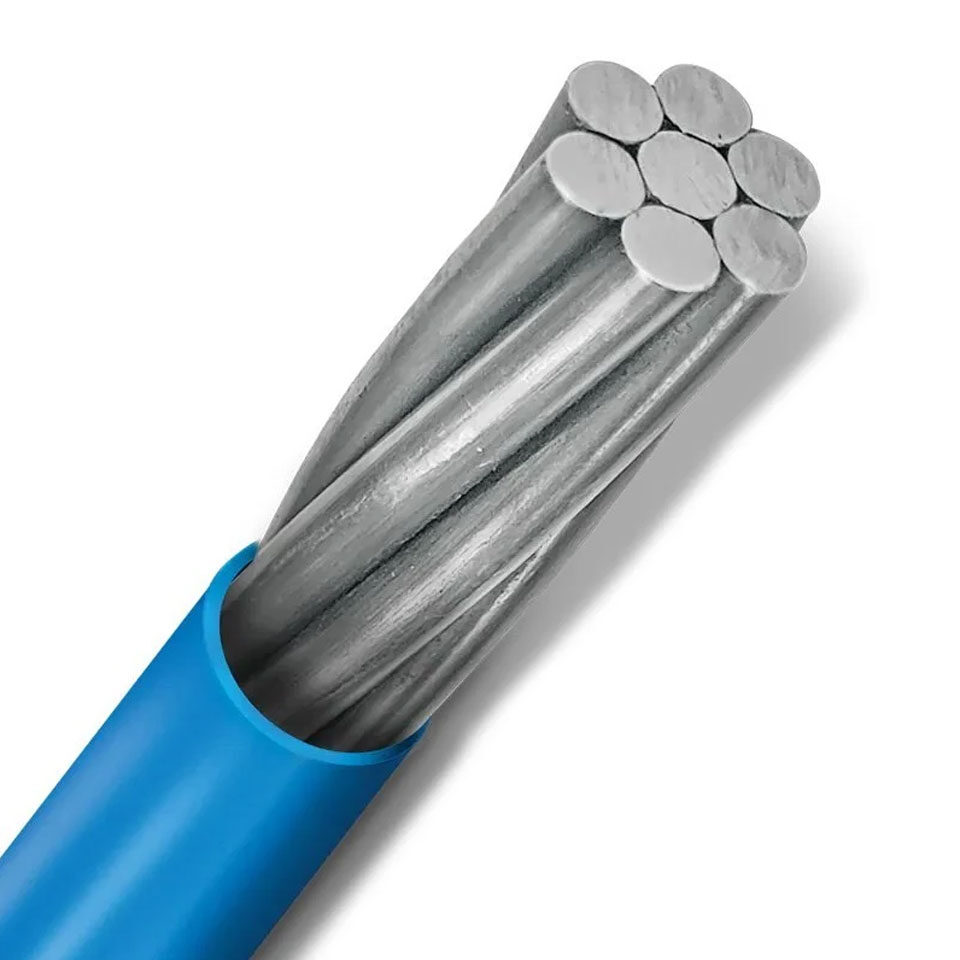

LRPC Strands (Bonded)

Kataria Industries Ltd. LRPC Strands, known for their exceptional mechanical properties, are distinguished by their superior quality, robustness, and resistance to adverse weather conditions. These uncoated strands are also referred to as bonded LRPC strands.

Polymer-Coated Grease/Wax-Filled LRPC Strands (Un-Bonded)

Our LRPC Strands are enhanced with a uniform, sleek, thermoplastic polymer sheathing that shields against contaminants, offers cushioning, and provides abrasion resistance, significantly extending the lifespan of the LRPC strands. In this product, the bare strands are impregnated with Grease/Wax before being enveloped in a polymer coating.

Galvanized LRPC Strands

Our Galvanized LRPC strands are zinc-coated to confer resistance to corrosion, resulting in an extended structural lifespan. This product can be tailored to meet specific technical requirements specified by the customer. The galvanization weight can be customized according to customer preferences, ranging from 190 to 340 grams per square meter.

Polymer-Coated Grease/Wax-Filled Galvanized LRPC Strands

Our LRPC strands are zinc-coated, and these galvanized strands receive an additional polymer coating. The application of Grease/Wax can be tailored to meet the customer's specific requirements.

Specialized LRPC Strands

These threads represent the embodiment of our company's relentless commitment to innovation. They are born from our firm's steadfast dedication to fostering new product development and the drive to surpass our own benchmarks continually.

LRPC / HT Strands

Technical Data Sheet (Indian Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.60 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Strand Designation | - | 9.60-1860-P | 12.90-1860-P | 15.20-1860-P | 15.70-1860-P |

| 2 | Nominal Diameter | mm | 9.60 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Toerance | - | General Tolerance will be Applicable based on Specified Weight Tolerance | |||

| 4 | Nominal Area | Sq. mm | 55 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 429.6 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 12 to 16 | 12 to 16 | 12 to 16 | 12 to 16 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Minimum 0.2% Proof Load | kN | 89.8 | 164 | 228 | 246 |

| 10 | Breaking Load (Minimum) | kN | 102 | 186 | 259 | 279 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 13 | Relaxation % (Under Load -70% of Specified Breaking Load.) | |||||

| (a) | For 100 Hours | % | Relaxation losses should not more than 1.8 | |||

| (b) | For 1000 Hours | % | Relaxation losses should not more than 2.5 | |||

Technical Data Sheet (European Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.30 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Steel Designation | – | Y1860S7 | Y1860S7 | Y1860S7 | Y1860S7 |

| 2 | Nominal Diameter | mm | 9.30 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | – | General Tolerance will be Applicable based on Specified Weight Tolerance Given | |||

| 4 | Nominal Area | Sq. mm | 52 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 406.1 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 14 to 18 | 14 to 18 | 14 to 18 | 14 to 18 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Proof force (Min. Value of 0.1%) | kN | 85.1 | 164 | 228 | 246 |

| 10 | Breaking Load | kN | 96.7 to 111 | 186 to 214 | 259 to 298 | 279 to 321 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Relaxation - 1000 Hrs (Maximum for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

Technical Data Sheet (British Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.30 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Steel Designation | – | Y1860S7 | Y1860S7 | Y1860S7 | Y1860S7 |

| 2 | Nominal Diameter | mm | 9.30 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | – | General Tolerance will be Applicable based on Specified Weight Tolerance Given | |||

| 4 | Nominal Area | Sq. mm | 52 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 406.1 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 14 to 18 | 14 to 18 | 14 to 18 | 14 to 18 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Proof force (Min. Value of 0.1%) | kN | 85.1 | 164 | 228 | 246 |

| 10 | Breaking Load | kN | 96.7 to 111 | 186 to 214 | 259 to 298 | 279 to 321 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Relaxation - 1000 Hrs (Maximum for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

Technical Data Sheet (American Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.53 mm | 12.70 mm | 15.20 mm | 15.70 mm | |||

| 1 | Grade | – | 270 [1860] | 270 [1860] | 270 [1860] | 270 [1860] |

| 2 | Nominal Diameter | mm | 9.53 | 12.70 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | mm | +0.65/-0.15 | +0.65/-0.15 | +0.65/-0.15 | +0.65/-0.15 |

| 4 | Nominal Area | Sq. mm | 55.00 | 98.70 | 140 | 150 |

| 5 | Unit Weight | Kg/Km | 430 | 780 | 1100 | 1200 |

| 6 | Weight Tolerance | - | General Tolerance will be Applicable based on Specified Diameter Tolerance Given | |||

| 7 | Lay Length | Times of Nominal Diameter of Strand | 12 to 16 | 12 to 16 | 12 to 16 | 12 to 16 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Minimum Load at 1.0% Extension | kN | 92.1 | 165.3 | 234.6 | 251.0 |

| 10 | Breaking Load (Minimum) | kN | 102 | 184 | 261 | 279 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Maximum Relaxation - 1000 Hrs (for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | 0.04 | 0.04 | 0.04 | 0.04 | |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

LRPC / HT Strands

Technical Data Sheet (Indian Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.60 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Strand Designation | - | 9.60-1860-P | 12.90-1860-P | 15.20-1860-P | 15.70-1860-P |

| 2 | Nominal Diameter | mm | 9.60 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Toerance | - | General Tolerance will be Applicable based on Specified Weight Tolerance | |||

| 4 | Nominal Area | Sq. mm | 55 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 429.6 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 12 to 16 | 12 to 16 | 12 to 16 | 12 to 16 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Minimum 0.2% Proof Load | kN | 89.8 | 164 | 228 | 246 |

| 10 | Breaking Load (Minimum) | kN | 102 | 186 | 259 | 279 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 13 | Relaxation % (Under Load -70% of Specified Breaking Load.) | |||||

| (a) | For 100 Hours | % | Relaxation losses should not more than 1.8 | |||

| (b) | For 1000 Hours | % | Relaxation losses should not more than 2.5 | |||

Technical Data Sheet (European Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.30 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Steel Designation | – | Y1860S7 | Y1860S7 | Y1860S7 | Y1860S7 |

| 2 | Nominal Diameter | mm | 9.30 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | – | General Tolerance will be Applicable based on Specified Weight Tolerance Given | |||

| 4 | Nominal Area | Sq. mm | 52 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 406.1 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 14 to 18 | 14 to 18 | 14 to 18 | 14 to 18 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Proof force (Min. Value of 0.1%) | kN | 85.1 | 164 | 228 | 246 |

| 10 | Breaking Load | kN | 96.7 to 111 | 186 to 214 | 259 to 298 | 279 to 321 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Relaxation - 1000 Hrs (Maximum for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

Technical Data Sheet (British Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.30 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Steel Designation | – | Y1860S7 | Y1860S7 | Y1860S7 | Y1860S7 |

| 2 | Nominal Diameter | mm | 9.30 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | – | General Tolerance will be Applicable based on Specified Weight Tolerance Given | |||

| 4 | Nominal Area | Sq. mm | 52 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 406.1 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 14 to 18 | 14 to 18 | 14 to 18 | 14 to 18 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Proof force (Min. Value of 0.1%) | kN | 85.1 | 164 | 228 | 246 |

| 10 | Breaking Load | kN | 96.7 to 111 | 186 to 214 | 259 to 298 | 279 to 321 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Relaxation - 1000 Hrs (Maximum for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

Technical Data Sheet (American Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.53 mm | 12.70 mm | 15.20 mm | 15.70 mm | |||

| 1 | Grade | – | 270 [1860] | 270 [1860] | 270 [1860] | 270 [1860] |

| 2 | Nominal Diameter | mm | 9.53 | 12.70 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | mm | +0.65/-0.15 | +0.65/-0.15 | +0.65/-0.15 | +0.65/-0.15 |

| 4 | Nominal Area | Sq. mm | 55.00 | 98.70 | 140 | 150 |

| 5 | Unit Weight | Kg/Km | 430 | 780 | 1100 | 1200 |

| 6 | Weight Tolerance | - | General Tolerance will be Applicable based on Specified Diameter Tolerance Given | |||

| 7 | Lay Length | Times of Nominal Diameter of Strand | 12 to 16 | 12 to 16 | 12 to 16 | 12 to 16 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Minimum Load at 1.0% Extension | kN | 92.1 | 165.3 | 234.6 | 251.0 |

| 10 | Breaking Load (Minimum) | kN | 102 | 184 | 261 | 279 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Maximum Relaxation - 1000 Hrs (for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | 0.04 | 0.04 | 0.04 | 0.04 | |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

LRPC / HT Strands

Technical Data Sheet (Indian Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.60 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Strand Designation | - | 9.60-1860-P | 12.90-1860-P | 15.20-1860-P | 15.70-1860-P |

| 2 | Nominal Diameter | mm | 9.60 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Toerance | - | General Tolerance will be Applicable based on Specified Weight Tolerance | |||

| 4 | Nominal Area | Sq. mm | 55 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 429.6 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 12 to 16 | 12 to 16 | 12 to 16 | 12 to 16 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Minimum 0.2% Proof Load | kN | 89.8 | 164 | 228 | 246 |

| 10 | Breaking Load (Minimum) | kN | 102 | 186 | 259 | 279 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 13 | Relaxation % (Under Load -70% of Specified Breaking Load.) | |||||

| (a) | For 100 Hours | % | Relaxation losses should not more than 1.8 | |||

| (b) | For 1000 Hours | % | Relaxation losses should not more than 2.5 | |||

Technical Data Sheet (European Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.30 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Steel Designation | – | Y1860S7 | Y1860S7 | Y1860S7 | Y1860S7 |

| 2 | Nominal Diameter | mm | 9.30 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | – | General Tolerance will be Applicable based on Specified Weight Tolerance Given | |||

| 4 | Nominal Area | Sq. mm | 52 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 406.1 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 14 to 18 | 14 to 18 | 14 to 18 | 14 to 18 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Proof force (Min. Value of 0.1%) | kN | 85.1 | 164 | 228 | 246 |

| 10 | Breaking Load | kN | 96.7 to 111 | 186 to 214 | 259 to 298 | 279 to 321 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Relaxation - 1000 Hrs (Maximum for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

Technical Data Sheet (British Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.30 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Steel Designation | – | Y1860S7 | Y1860S7 | Y1860S7 | Y1860S7 |

| 2 | Nominal Diameter | mm | 9.30 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | – | General Tolerance will be Applicable based on Specified Weight Tolerance Given | |||

| 4 | Nominal Area | Sq. mm | 52 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 406.1 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 14 to 18 | 14 to 18 | 14 to 18 | 14 to 18 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Proof force (Min. Value of 0.1%) | kN | 85.1 | 164 | 228 | 246 |

| 10 | Breaking Load | kN | 96.7 to 111 | 186 to 214 | 259 to 298 | 279 to 321 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Relaxation - 1000 Hrs (Maximum for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

Technical Data Sheet (American Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.53 mm | 12.70 mm | 15.20 mm | 15.70 mm | |||

| 1 | Grade | – | 270 [1860] | 270 [1860] | 270 [1860] | 270 [1860] |

| 2 | Nominal Diameter | mm | 9.53 | 12.70 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | mm | +0.65/-0.15 | +0.65/-0.15 | +0.65/-0.15 | +0.65/-0.15 |

| 4 | Nominal Area | Sq. mm | 55.00 | 98.70 | 140 | 150 |

| 5 | Unit Weight | Kg/Km | 430 | 780 | 1100 | 1200 |

| 6 | Weight Tolerance | - | General Tolerance will be Applicable based on Specified Diameter Tolerance Given | |||

| 7 | Lay Length | Times of Nominal Diameter of Strand | 12 to 16 | 12 to 16 | 12 to 16 | 12 to 16 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Minimum Load at 1.0% Extension | kN | 92.1 | 165.3 | 234.6 | 251.0 |

| 10 | Breaking Load (Minimum) | kN | 102 | 184 | 261 | 279 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Maximum Relaxation - 1000 Hrs (for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | 0.04 | 0.04 | 0.04 | 0.04 | |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

LRPC / HT Strands

Technical Data Sheet (Indian Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.60 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Strand Designation | - | 9.60-1860-P | 12.90-1860-P | 15.20-1860-P | 15.70-1860-P |

| 2 | Nominal Diameter | mm | 9.60 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Toerance | - | General Tolerance will be Applicable based on Specified Weight Tolerance | |||

| 4 | Nominal Area | Sq. mm | 55 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 429.6 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 12 to 16 | 12 to 16 | 12 to 16 | 12 to 16 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Minimum 0.2% Proof Load | kN | 89.8 | 164 | 228 | 246 |

| 10 | Breaking Load (Minimum) | kN | 102 | 186 | 259 | 279 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 13 | Relaxation % (Under Load -70% of Specified Breaking Load.) | |||||

| (a) | For 100 Hours | % | Relaxation losses should not more than 1.8 | |||

| (b) | For 1000 Hours | % | Relaxation losses should not more than 2.5 | |||

Technical Data Sheet (European Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.30 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Steel Designation | – | Y1860S7 | Y1860S7 | Y1860S7 | Y1860S7 |

| 2 | Nominal Diameter | mm | 9.30 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | – | General Tolerance will be Applicable based on Specified Weight Tolerance Given | |||

| 4 | Nominal Area | Sq. mm | 52 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 406.1 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 14 to 18 | 14 to 18 | 14 to 18 | 14 to 18 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Proof force (Min. Value of 0.1%) | kN | 85.1 | 164 | 228 | 246 |

| 10 | Breaking Load | kN | 96.7 to 111 | 186 to 214 | 259 to 298 | 279 to 321 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Relaxation - 1000 Hrs (Maximum for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

Technical Data Sheet (British Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.30 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Steel Designation | – | Y1860S7 | Y1860S7 | Y1860S7 | Y1860S7 |

| 2 | Nominal Diameter | mm | 9.30 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | – | General Tolerance will be Applicable based on Specified Weight Tolerance Given | |||

| 4 | Nominal Area | Sq. mm | 52 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 406.1 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 14 to 18 | 14 to 18 | 14 to 18 | 14 to 18 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Proof force (Min. Value of 0.1%) | kN | 85.1 | 164 | 228 | 246 |

| 10 | Breaking Load | kN | 96.7 to 111 | 186 to 214 | 259 to 298 | 279 to 321 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Relaxation - 1000 Hrs (Maximum for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

Technical Data Sheet (American Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.53 mm | 12.70 mm | 15.20 mm | 15.70 mm | |||

| 1 | Grade | – | 270 [1860] | 270 [1860] | 270 [1860] | 270 [1860] |

| 2 | Nominal Diameter | mm | 9.53 | 12.70 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | mm | +0.65/-0.15 | +0.65/-0.15 | +0.65/-0.15 | +0.65/-0.15 |

| 4 | Nominal Area | Sq. mm | 55.00 | 98.70 | 140 | 150 |

| 5 | Unit Weight | Kg/Km | 430 | 780 | 1100 | 1200 |

| 6 | Weight Tolerance | - | General Tolerance will be Applicable based on Specified Diameter Tolerance Given | |||

| 7 | Lay Length | Times of Nominal Diameter of Strand | 12 to 16 | 12 to 16 | 12 to 16 | 12 to 16 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Minimum Load at 1.0% Extension | kN | 92.1 | 165.3 | 234.6 | 251.0 |

| 10 | Breaking Load (Minimum) | kN | 102 | 184 | 261 | 279 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Maximum Relaxation - 1000 Hrs (for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | 0.04 | 0.04 | 0.04 | 0.04 | |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

LRPC / HT Strands

Technical Data Sheet (Indian Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.60 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Strand Designation | - | 9.60-1860-P | 12.90-1860-P | 15.20-1860-P | 15.70-1860-P |

| 2 | Nominal Diameter | mm | 9.60 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Toerance | - | General Tolerance will be Applicable based on Specified Weight Tolerance | |||

| 4 | Nominal Area | Sq. mm | 55 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 429.6 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 12 to 16 | 12 to 16 | 12 to 16 | 12 to 16 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Minimum 0.2% Proof Load | kN | 89.8 | 164 | 228 | 246 |

| 10 | Breaking Load (Minimum) | kN | 102 | 186 | 259 | 279 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 13 | Relaxation % (Under Load -70% of Specified Breaking Load.) | |||||

| (a) | For 100 Hours | % | Relaxation losses should not more than 1.8 | |||

| (b) | For 1000 Hours | % | Relaxation losses should not more than 2.5 | |||

Technical Data Sheet (European Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.30 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Steel Designation | – | Y1860S7 | Y1860S7 | Y1860S7 | Y1860S7 |

| 2 | Nominal Diameter | mm | 9.30 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | – | General Tolerance will be Applicable based on Specified Weight Tolerance Given | |||

| 4 | Nominal Area | Sq. mm | 52 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 406.1 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 14 to 18 | 14 to 18 | 14 to 18 | 14 to 18 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Proof force (Min. Value of 0.1%) | kN | 85.1 | 164 | 228 | 246 |

| 10 | Breaking Load | kN | 96.7 to 111 | 186 to 214 | 259 to 298 | 279 to 321 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Relaxation - 1000 Hrs (Maximum for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

Technical Data Sheet (British Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.30 mm | 12.90 mm | 15.20 mm | 15.70 mm | |||

| 1 | Steel Designation | – | Y1860S7 | Y1860S7 | Y1860S7 | Y1860S7 |

| 2 | Nominal Diameter | mm | 9.30 | 12.90 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | – | General Tolerance will be Applicable based on Specified Weight Tolerance Given | |||

| 4 | Nominal Area | Sq. mm | 52 | 100 | 139 | 150 |

| 5 | Unit Weight | Kg/Km | 406.1 | 781 | 1086 | 1172 |

| 6 | Weight Tolerance | % | ±2 | ±2 | ±2 | ±2 |

| 7 | Lay Length | Times of Nominal Diameter of Strand | 14 to 18 | 14 to 18 | 14 to 18 | 14 to 18 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Proof force (Min. Value of 0.1%) | kN | 85.1 | 164 | 228 | 246 |

| 10 | Breaking Load | kN | 96.7 to 111 | 186 to 214 | 259 to 298 | 279 to 321 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Relaxation - 1000 Hrs (Maximum for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

Technical Data Sheet (American Specification)

| Sr.No. | Descriptions | UOM | Specified Values | |||

|---|---|---|---|---|---|---|

| 9.53 mm | 12.70 mm | 15.20 mm | 15.70 mm | |||

| 1 | Grade | – | 270 [1860] | 270 [1860] | 270 [1860] | 270 [1860] |

| 2 | Nominal Diameter | mm | 9.53 | 12.70 | 15.20 | 15.70 |

| 3 | Diameter Tolerance | mm | +0.65/-0.15 | +0.65/-0.15 | +0.65/-0.15 | +0.65/-0.15 |

| 4 | Nominal Area | Sq. mm | 55.00 | 98.70 | 140 | 150 |

| 5 | Unit Weight | Kg/Km | 430 | 780 | 1100 | 1200 |

| 6 | Weight Tolerance | - | General Tolerance will be Applicable based on Specified Diameter Tolerance Given | |||

| 7 | Lay Length | Times of Nominal Diameter of Strand | 12 to 16 | 12 to 16 | 12 to 16 | 12 to 16 |

| 8 | Lay Direction | RH or LH | RH | RH | RH | RH |

| 9 | Minimum Load at 1.0% Extension | kN | 92.1 | 165.3 | 234.6 | 251.0 |

| 10 | Breaking Load (Minimum) | kN | 102 | 184 | 261 | 279 |

| 11 | Elongation Minimum | % | 3.5 | 3.5 | 3.5 | 3.5 |

| 12 | Maximum Relaxation - 1000 Hrs (for 70 % Initial Load) | % | 2.5 | 2.5 | 2.5 | 2.5 |

| 13 | Modulus of Elasticity | Gpa or kN/Sq mm | May be Taken as 195 | |||

| 14 | Chemical Composition | |||||

| (a) | Sulphur (max) | 0.04 | 0.04 | 0.04 | 0.04 | |

| (b) | Phosphorus (max) | % | 0.04 | 0.04 | 0.04 | 0.04 |

Why You Should Trust Kataria Industries Ltd. LRPC?

Coil Packaging

Kataria Industries Ltd. LRPC Strands are available in reel-less (cheese) coils, with weights ranging from 1 MT to 3.9 MT, tailored to meet our customers’ specific needs. These coils are carefully secured to ensure a compact arrangement and are packed and palletized as per the customer’s preferences. Additionally, the beginning end of the strand is clearly marked for easy identification within the coil. These coils can be effortlessly extracted from the center for added convenience.

- Strapping at Eight places over bare coils.

- Wrapping of Three Layer Using VPI Paper / Polythene Sheet.

- Strapping at Six places post Polythene Wrapping.

- Coil Supported with Wooden Blocks or Pallets.

- Fixing of Identification Plate.

Oiled Condition

Dry Condition

Packed Coil

Indian Testing Labs

Indian Institute of Technology (IIT), Chennai

Bureau Veritas (India) Pvt. Ltd. (BVQI), Navi Mumbai

AnuLab Industrial Testing & Analytical Laboratories, Agra

Shriram Institute for Industrial Research, Delhi

Global Lab, Navi Mumbai

Divine Metallurgical Services Pvt. Ltd., Ahmedabad

Various Others...

International Testing Lab

Liuzhou OVM Machinery Co. Ltd., Liuzhou - China

Dubai Central Laboratory, Dubai - UAE